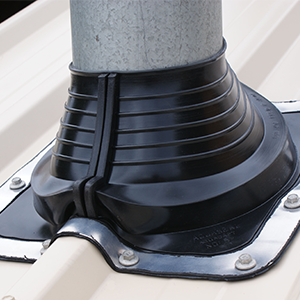

Aquaseal Pipe Flashings

Yes. Aquarius polymers are formulated to be Ozone and UV resistant.

Yes, after installation. We recommend using 100% acrylic paint.

Yes, provided a twin or triple skin flue has been installed. Aquarius Rubber recommends their Silicone polymer Pipe Flashings for high temperature applications. Under no circumstances should any polymer pipe flashing be used on single skin flue discharging from a wood heater.

Many trades people still use the silicone flashing for heater flues.

When the flue type is a twin or triple skin, tests have shown that the Aquarius black EPDM pipe flashing will adequately do the job and should not be affected by the passive flue heat.

Yes. Aquarius Rubber has developed two sizes designed to suit square pipes from 25mm to 150mm. (Aquaseal Square Flasher & Versatile Square Flasher)

Aquarius Aquaseal's have measurements on their flashings to help guide the installer for the correct pipe O.D.

If measurements are not available, use the rule of subtracting 18% off the outside diameter of the pipe. Example, if the pipe is 100mm in OD, subtract 18% of 100mm, this will provide the recommended pipe flashing I.D. of 82mm for a 100mm OD pipe. This will provide a good interference fit between the pipe flashing and pipe.

Each installation can be different and as a guide, fixings should be between 20 – 50mm apart. They should not be more than 50mm apart.

We recommend a sharp pair of scissors to cut our pipe flashing for the correct pipe size. Ensure there are no accidental nicks in the polymer, as this will continue to split/tear over time.

Tip: Ensure the blades are sharp with no contamination e.g. glue or any accumulated dirt.

The Aqua Tile, Versatile Aluminium, Flexatile & Versatile LDX are all suitable for drinking water catchments. We do not recommend using a flashing that has a lead base.

No, silicone sealant should not be used where the Pipe Flashing seals around the pipe. This can cause water leaks as the silicone can crack over time and allow water ingress. If the pipe has a seam, then a small amount of sealant can be used along the seam up to the lip of the Pipe Flashing. Click on the following link for further details - Aquadapt Installation Overview.pdf

EPDM can withstand temperatures between -40 C° to +115 C°.

Silicone can withstand temperatures between -60 C° to +200 C°

Aquarius Rubber provides a 25 year warranty against defects in material on all pipe flashings. We recommed a licenced plumber for all Aquaseal installations. Aquarius Aquaseal Pipe Flashings have been manufactured in Australia for over 40 years and to this day we can find installations of our original products that are are still performing as expected.

We recommend Class 3 or Class 4 hex head self-drilling screws minimum of 16mm long with a rubber washer.

We recommend a neutral cure sealant.

Aquaseal Expansion Strip Joint

Yes. A minimum of Stainless Steel 304 screws must be used

We recommend that fastening screws are no greater than 40mm apart from the screws centre heads

We recommend a gap of 25mm to 30mm between the two box gutters, however it is preferred by most installers to overlap the box gutters by 30mm to 40mm.

A minimum of Stainless Steel 304 grade screws must be used.

We recommend a neutral cure sealant.

Aquatools

Styroscrew – Fixing for foam walls

Yes, Styroscrew can be used on Hebel. The same installation method applies.

Before screwing the Styroscrew into the rendered foam wall, we recommend drilling a hole with a 10mm drill bit to avoid cracking the rendered wall.

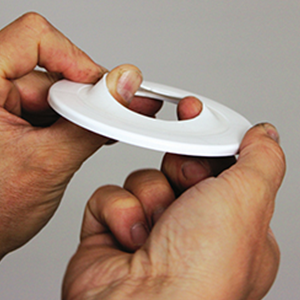

Styrowedge – Fixing for foam walls

Yes, however we recommend Styroscrew over Styrowedge

We recommend using a sharp tradies knife to create a horizontal slot into the rendered wall and into the foam board. With a hammer, gently tap the combined plates until flush with the wall.

Red Back

Cleaning Abrasive

Yes, the larger Cleaning Abrasive size comes in a 5 meter roll. Code Red413

There are two sizes available. Cleaning Abrasive standard comes with two strips at 60cm. Cleaning Abrasive large comes in a five metre roll.

No, Cleaning Abrasive is metal-free.

Drain Dye

We do not recommend using Drain Dye on porous surfaces.

Sunlight will break down the product in a relatively short period. The exact time for this will vary depending on the strength of the UV light. Even under weak UV, the dyes will break down in a matter of days.

Drain Dye is hydrophilic, (that is, bonds readily with water), therefore, it is easily cleaned up with, or washed away with water. To speed up the process household cleaning bleach can be used to break down drain dye. Always use bleach in accordance with the manufacturer’s instructions.

To prevent staining, always test the product on a small non conspicuous area prior to use. If the product is difficult to remove from the substrate find another method or product to test for leaks or water flows.

Always use Red Back Drain Dye as per the MSDS.

As a general rule, 20 grams of Drain Dye will provide a strong visual in 200 litres of water. 1kg of Drain Dye will provide a strong visual in 10,000 litres of water.

Yes, Drain Dye is non-toxic. They are biodegradable and safe for the environment. Please refer to the MSDS for further information

The red Drain Dye is a highly concentrated food dye whereas the green contains fluorescein and sodium sulphate.Please refer to the MSDS for more information

Silicone Clean Up

Yes. Apply Silicone Clean Up to a rag and place it directly to the cured silicone. Wait approximately 1-2 minutes and remove with scraper.

Silicone Clean Up should not be used on painted surfaces.

Drain Dye is hydrophilic, (that is, bonds readily with water), therefore, it is easily cleaned up with, or washed away with water. To speed up the process household cleaning bleach can be used to break down drain dye. Always use bleach in accordance with the manufacturer’s instructions.

To prevent staining, always test the product on a small non conspicuous area prior to use. If the product is difficult to remove from the substrate find another method or product to test for leaks or water flows.

Always use Red Back Drain Dye as per the MSDS.

Tube Past

Yes

White PTFE Tape

No, this tape cannot be used on gas threads. This tape is suitable for potable water.

Wonder Juice

Yes. This will require some force and we recommend using a wrench tool.

No, Wonder Juice will not work on any plastic threads.

We recommend waiting 15 minutes before applying pressure.

Full cure takes 24hrs, however pressure can be applied after 15 minutes.

Use Wonder Juice within 18 months of opening.

Wonder Juice requires air to stay uncured. Once air is eliminated, Wonder Juice starts to cure.